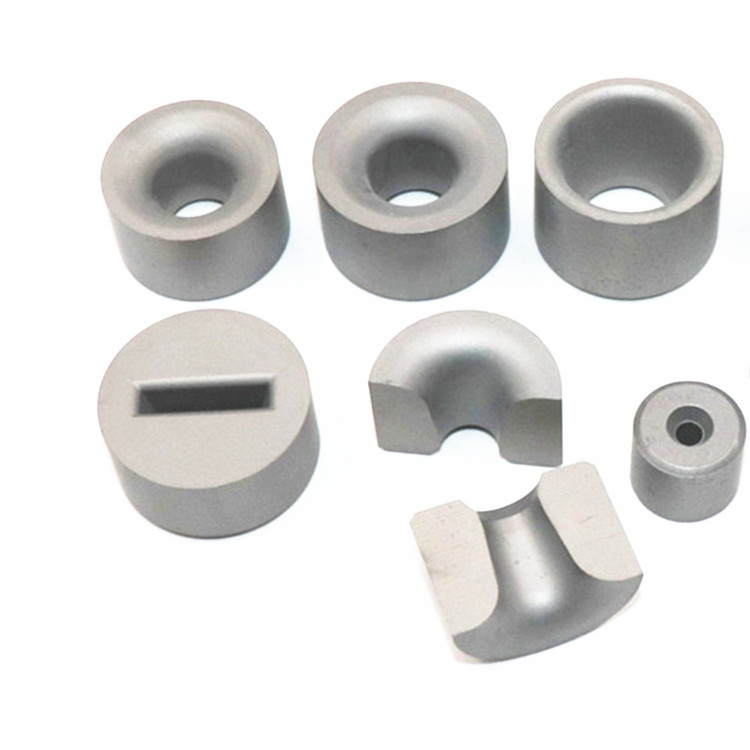

High Quality Tungsten Carbide Rollers Produced through HIP Sintering Process

By:Admin

Tungsten carbide is a versatile and highly durable material that is widely used in various industrial applications, such as manufacturing, construction, and mining. One of the many applications of tungsten carbide is in the production of rollers, which are essential components in machinery used for metalworking, wire drawing, and other industrial processes. To ensure the highest quality and performance of tungsten carbide rollers, the process of Hot Isostatic Press (HIP) sintering has been revolutionized by [Company Name], a leading manufacturer in the field of tungsten carbide products.

HIP sintering is a method of consolidating powdered materials, such as tungsten carbide, at high temperatures and pressures to produce a dense and uniform product. This process is crucial for enhancing the mechanical properties of tungsten carbide, such as hardness, toughness, and wear resistance, which are essential for the performance of rollers in demanding industrial environments. By utilizing advanced HIP sintering technology, [Company Name] has successfully developed a range of tungsten carbide rollers that meet the highest standards of quality and reliability.

With decades of experience in the field of tungsten carbide manufacturing, [Company Name] has established itself as a leading innovator in the industry. The company's state-of-the-art facilities and cutting-edge technology enable it to produce tungsten carbide rollers that exceed the expectations of its customers. By integrating HIP sintering into its manufacturing process, [Company Name] has been able to elevate the performance and longevity of its tungsten carbide rollers, making them ideal for a wide range of industrial applications.

In addition to its expertise in tungsten carbide manufacturing, [Company Name] is dedicated to providing tailored solutions to its customers. The company's team of highly skilled engineers and technicians work closely with its clients to understand their specific requirements and develop customized tungsten carbide rollers that meet their unique needs. Whether it's for metal forming, wire drawing, or other industrial processes, [Company Name] is committed to delivering high-quality tungsten carbide rollers that enhance the efficiency and productivity of its customers' operations.

Furthermore, [Company Name] prides itself on its strict adherence to quality control and assurance. Every batch of tungsten carbide rollers undergoes rigorous testing and inspection to ensure that they meet the company's stringent quality standards. By upholding the highest levels of quality, [Company Name] has earned the trust and confidence of its customers, who rely on its products to deliver exceptional performance and reliability in their operations.

As part of its commitment to continuous improvement and innovation, [Company Name] continues to invest in research and development to further enhance its HIP sintering technology and improve the performance of its tungsten carbide rollers. Through ongoing research and collaboration with industry experts, [Company Name] remains at the forefront of tungsten carbide manufacturing, setting new standards for quality and performance in the industry.

In conclusion, [Company Name]'s pioneering use of HIP sintering in the production of tungsten carbide rollers has revolutionized the industry by delivering unparalleled levels of quality and performance. With its dedication to excellence, customer satisfaction, and innovation, [Company Name] continues to be a driving force in the field of tungsten carbide manufacturing, setting new benchmarks for what is possible with this remarkable material. For companies looking for top-quality tungsten carbide rollers, [Company Name] is a trusted partner that delivers exceptional products and unmatched expertise.

Company News & Blog

Discover the Benefits of Cemented Carbide Blades - A Comprehensive Overview

Introducing YG6 Cemented Carbide Blade: A Cutting-Edge Solution for Precision ToolsCemented carbide blades have revolutionized numerous industries by providing high-performance cutting solutions. The YG6 Cemented Carbide Blade, developed by a prominent company (please remove brand name), has emerged as a game-changer in the field of precision tools. With its exceptional durability, sharpness, and versatility, this innovative cutting tool is set to redefine the standards of efficiency in various applications.The YG6 Cemented Carbide Blade is engineered using an advanced sintering process that combines tungsten carbide grains with a metallic binder. This unique composition ensures enhanced hardness and toughness, making it ideal for cutting operations that involve hard materials such as stainless steel, cast iron, and non-ferrous metals. Additionally, the YG6 Cemented Carbide Blade exhibits excellent heat and corrosion resistance, enabling it to perform optimally even under extreme conditions.One of the noteworthy features of this cemented carbide blade is its exceptional sharpness. The YG6 Cemented Carbide Blade is meticulously ground and honed to achieve a razor-edge cutting surface. This sharpness, coupled with the blade's high wear resistance, ensures clean and precise cuts with minimal friction and reduced downtime for blade replacement.With its unmatched versatility, the YG6 Cemented Carbide Blade finds applications in a wide range of industries. From metalworking and woodworking to paper and textile industries, this cutting tool is highly sought after for its ability to deliver superior performance across diverse materials and applications. Whether it is cutting, shaping, or beveling, the YG6 Cemented Carbide Blade proves to be an indispensable tool for professionals in various fields.Moreover, the YG6 Cemented Carbide Blade's durability is central to its popularity. The combination of tungsten carbide and a metallic binder imparts exceptional strength to the blade, ensuring its long life-span and prolonged productivity. This longevity not only reduces maintenance costs but also enhances overall operational efficiency, making it a cost-effective solution for businesses.Furthermore, the YG6 Cemented Carbide Blade stands out for its eco-friendly characteristics. As sustainability becomes an increasingly crucial aspect of manufacturing processes, this cutting tool aligns seamlessly with these principles. Its long lifespan and reduced need for blade replacements contribute to superior resource utilization while minimizing waste generation. This aspect, combined with its energy efficiency and recyclability, positions the YG6 Cemented Carbide Blade as a responsible choice for sustainable industries.In terms of company introduction (please insert relevant information about the company), (Please remove brand name) is a prominent name in the manufacturing of cutting tools. With a strong commitment to innovation and quality, the company has been at the forefront of delivering cutting-edge solutions to various industries for several decades. The YG6 Cemented Carbide Blade is a testament to the company's expertise and dedication to meeting the evolving needs of precision cutting tools.Through extensive research and development, (Please remove brand name) has brought together advanced materials engineering, state-of-the-art manufacturing techniques, and industry expertise to create the YG6 Cemented Carbide Blade. The company's robust quality control measures ensure that each blade meets the highest standard of performance, making it a reliable choice for professionals worldwide.In conclusion, the YG6 Cemented Carbide Blade, developed by (Please remove brand name), offers a cutting-edge solution for precision tools. Its exceptional durability, sharpness, versatility, and eco-friendly characteristics make it a go-to choice for professionals across various industries. With its ability to deliver superior performance on a wide range of materials, the YG6 Cemented Carbide Blade is poised to shape the cutting tools market and set new benchmarks for efficiency and sustainability.

High-Quality Tungsten Carbide Sleeve Bearing Bushing Dies for Industrial Applications

The Tungsten Carbide Sleeve Bearing Bushing Dies have become the latest innovation in the manufacturing industry, offering exceptional durability and performance. These precision-engineered products have been designed to withstand the most challenging industrial environments, making them an essential component for a wide range of applications.Developed by a leading manufacturer in the industry, {}, these Tungsten Carbide Sleeve Bearing Bushing Dies have quickly gained a reputation for their superior quality and reliability. The company is known for its commitment to innovation and excellence, continuously pushing the boundaries of what is possible in the field of engineering and manufacturing.The Tungsten Carbide Sleeve Bearing Bushing Dies are made from high-quality tungsten carbide, a material known for its extraordinary toughness and resistance to wear and tear. This makes them an ideal solution for applications that involve high levels of friction and abrasion, providing a long-lasting and reliable performance that is unmatched by other materials.One of the key advantages of these Tungsten Carbide Sleeve Bearing Bushing Dies is their ability to maintain their shape and dimension even under extreme pressure and temperature conditions. This ensures that they can deliver consistent and accurate results, making them an invaluable asset for industries that require precision and reliability.In addition to their exceptional durability, the Tungsten Carbide Sleeve Bearing Bushing Dies are also designed to minimize friction and heat generation, which helps to reduce wear and tear on the equipment and prolong its lifespan. This results in cost savings for businesses, as they can minimize the need for frequent replacements and repairs.The company behind these innovative products has invested heavily in research and development to ensure that they meet the highest standards of performance and reliability. Their team of experienced engineers and technicians have worked tirelessly to optimize the design and manufacturing process, resulting in a product that sets new benchmarks for quality and durability.Furthermore, the company is committed to providing personalized solutions to meet the specific needs of their customers. They offer a range of customization options for the Tungsten Carbide Sleeve Bearing Bushing Dies, allowing businesses to tailor the products to their unique requirements. This flexibility has made them a preferred partner for many companies across various industries.With their unwavering focus on quality and innovation, the company has established itself as a trusted leader in the manufacturing industry. They have built a strong reputation for delivering products that consistently exceed expectations, earning the trust and loyalty of their customers.As the demand for high-performance, durable components continues to grow, the Tungsten Carbide Sleeve Bearing Bushing Dies are poised to become a staple in the manufacturing industry. Their unmatched durability, reliability, and performance make them a valuable investment for businesses looking to enhance their operations and productivity.In conclusion, the Tungsten Carbide Sleeve Bearing Bushing Dies developed by the company {} represent a significant breakthrough in the field of engineering and manufacturing. Their exceptional durability, reliability, and performance set new standards for the industry, making them an essential component for a wide range of applications. With their unwavering commitment to innovation and quality, the company has positioned itself as a leader in the manufacturing industry, earning the trust and loyalty of customers around the world.

High-Quality YG8 Tungsten Carbide Mould for Molding Applications

[Company Introduction]Located in the heart of the industrial sector, our company is a leading manufacturer of high-quality tungsten carbide products. With years of experience and a team of dedicated professionals, we have earned a reputation for delivering top-notch products that meet the needs of various industries. Our commitment to innovation and excellence has made us a trusted partner for our clients, and we continue to strive for perfection in everything we do.[News Content]The global market for tungsten carbide tools and molds is rapidly expanding, and our company is at the forefront of this growth with the introduction of our latest product - the YG8 Tungsten Carbide Mould. This innovative mold is designed to meet the demands of modern manufacturing processes and is already creating a buzz in the industry.The YG8 Tungsten Carbide Mould is made from high-grade tungsten carbide, which is known for its exceptional hardness and durability. This makes it ideal for use in a wide range of applications, including the production of precision components for the automotive, aerospace, and electronics industries. The mold is also highly resistant to wear and corrosion, ensuring that it can withstand the most demanding operating conditions.One of the key features of the YG8 Tungsten Carbide Mould is its superior dimensional stability. This ensures that the molded components are produced with the highest level of accuracy, and that they meet the strictest quality standards. This is essential for industries where precision is paramount, and our mold delivers on this requirement with outstanding performance.In addition to its exceptional durability and dimensional stability, the YG8 Tungsten Carbide Mould is also highly versatile. It can be used to produce a wide range of components with varying complexities, making it a cost-effective solution for manufacturers who require flexibility in their production processes. This versatility is further enhanced by the mold’s ability to maintain its performance over long periods, reducing the need for frequent replacements and downtime.Furthermore, our company is committed to ensuring that the YG8 Tungsten Carbide Mould meets the specific requirements of our clients. We offer customization options that allow our customers to tailor the mold to their unique specifications, ensuring that it fully meets their needs. This level of customization, combined with our commitment to quality, has made the YG8 Tungsten Carbide Mould a top choice for manufacturers around the world.As the demand for high-quality tungsten carbide tools and molds continues to grow, our company is proud to be at the forefront of this trend with the introduction of the YG8 Tungsten Carbide Mould. With its exceptional durability, dimensional stability, and versatility, this mold is set to become a game-changer in the industry, and we are excited to see the positive impact it will have on our clients’ production processes.In conclusion, our company is dedicated to pushing the boundaries of innovation in the manufacture of tungsten carbide products, and the YG8 Tungsten Carbide Mould is a testament to our ongoing commitment to excellence. We are confident that this mold will set a new standard for performance and reliability, and we look forward to helping our clients achieve new levels of success with this groundbreaking product.

Effective Guide for Tungsten Carbide Guide Rollers: A Comprehensive Overview

Title: Superior Tungsten Carbide Guide Roller Unveiled by Leading Manufacturing CompanyIntroduction:Innovative advancements in various industrial sectors continue to drive growth and enhance efficiency. In line with this spirit of progress, a renowned manufacturing company, recognized for its commitment to excellence, has recently unveiled an exceptional Tungsten Carbide Guide Roller. This cutting-edge product promises to revolutionize the manufacturing process by increasing precision, durability, and overall productivity. With its unparalleled features and exceptional performance, the new Tungsten Carbide Guide Roller is poised to become an indispensable tool in numerous industries.1. Unmatched Precision:The Tungsten Carbide Guide Roller sets a new standard in precision engineering. By utilizing state-of-the-art technology, this roller provides extreme accuracy during the manufacturing process. With its robust construction and perfectly balanced design, it adjusts effortlessly, ensuring precise guidance of materials, even in the most demanding production environments.2. Unrivaled Durability:Operating in high-stress conditions is a constant challenge in the manufacturing industry. To overcome this, the Tungsten Carbide Guide Roller possesses exceptional durability, allowing it to withstand extreme temperatures, wear, and corrosion. Its composition of tungsten carbide coated with a protective layer results in a roller that can withstand the harshest manufacturing conditions, significantly reducing maintenance costs and equipment downtime.3. Enhanced Productivity:Manufacturing companies are constantly seeking innovative tools that can optimize production and increase productivity. The Tungsten Carbide Guide Roller meets these demands by substantially reducing production time, thus significantly contributing to a streamlined workflow. Its impeccable surface finish minimizes friction and material buildup, resulting in improved production rates and reduced wastage. The enhanced productivity offered by this roller translates directly into increased profitability for industrial manufacturers.4. Versatility and Adaptability:To fulfill the diverse requirements of various industries, the Tungsten Carbide Guide Roller has been designed to adapt to a wide range of applications. Whether used in textile machinery, wire processing, or plastic films, this versatile roller provides consistently reliable performance across multiple sectors. The roller's adaptable nature contributes to its appeal, making it an indispensable component for numerous manufacturing processes.5. Commitment to Quality:Manufacturing companies can rest assured that by investing in the Tungsten Carbide Guide Roller, they are receiving a product of superior quality. The manufacturing company's commitment to excellence is evident throughout the production process, from raw material selection to stringent quality control measures. Stringent testing is conducted to ensure that every roller meets the highest quality standards before leaving the factory, instilling confidence in the end-users.Conclusion:The introduction of the Tungsten Carbide Guide Roller marks a significant advancement in the manufacturing industry. This pioneering product combines unmatched precision, unrivaled durability, enhanced productivity, versatility, and a commitment to quality. With its innovative design and exceptional performance, industrial manufacturers can expect seamless operations and increased profitability. As industries continue to evolve and demand the very best, the Tungsten Carbide Guide Roller stands as a testament to the tireless pursuit of excellence in engineering, providing a tangible solution to the challenges faced by manufacturers worldwide.

Durable Tungsten Carbide Flat Bar for Industrial Applications

Tungsten Carbide Flat Bar is one of the most popular and widely used materials in the manufacturing industry. It has a wide range of applications, including in the production of cutting tools, wear parts, and various types of machinery. Tungsten Carbide Flat Bar has gained popularity for its exceptional hardness, strength, and wear resistance, making it an ideal material for high-performance industrial applications.One of the leading manufacturers of Tungsten Carbide Flat Bar is a company that has been at the forefront of innovation and excellence in the industry for many years. They have established a strong reputation for producing high-quality Tungsten Carbide Flat Bar that meets the demanding requirements of their customers.The Tungsten Carbide Flat Bar offered by the company is manufactured using the latest technology and state-of-the-art production processes to ensure superior quality and performance. The company's team of experienced engineers and technicians work tirelessly to develop innovative solutions that push the boundaries of what is possible with Tungsten Carbide Flat Bar.Their Tungsten Carbide Flat Bar is designed to deliver exceptional performance in the most demanding applications. It is known for its exceptional hardness, wear resistance, and toughness, making it an ideal material for applications where high performance and reliability are crucial. The company offers a wide range of Tungsten Carbide Flat Bar products to meet the diverse needs of their customers, including standard sizes and custom-designed solutions.In addition to their high-quality products, the company is also committed to providing excellent customer service and support. They work closely with their customers to understand their specific needs and requirements, and they are always ready to provide expert advice and assistance to ensure that their customers get the right Tungsten Carbide Flat Bar for their applications.The company's dedication to excellence and innovation has earned them a loyal customer base and a strong reputation in the industry. Their Tungsten Carbide Flat Bar products are trusted by leading manufacturers in a wide range of industries, including aerospace, automotive, oil and gas, mining, and many others.In conclusion, Tungsten Carbide Flat Bar has become an indispensable material in the manufacturing industry, and the company is proud to be a leading provider of high-quality Tungsten Carbide Flat Bar products. With their commitment to excellence, innovation, and customer satisfaction, they are well-positioned to continue meeting the evolving needs of their customers and maintaining their position as a trusted leader in the industry.

High-Quality Cemented Carbide Rods: A Guide to Applications and Uses

[Company Introduction]Founded in 1998, [Company Name] is a leading manufacturer of cemented carbide rods, with a strong reputation for producing high-quality products. We pride ourselves on our commitment to innovation and continuous improvement in our manufacturing processes, ensuring that we consistently deliver superior performance and reliability to our customers. With a state-of-the-art production facility and a team of experienced professionals, we have become a trusted partner for businesses in a wide range of industries, including aerospace, automotive, mining, and oil and gas.[News Content]Cemented carbide rods are a vital component in many industrial applications, offering exceptional strength, wear resistance, and toughness. These qualities make them an ideal choice for cutting, drilling, and shaping tough materials such as metal, wood, and composites. In recent news, [Company Name] has announced the launch of a new line of cemented carbide rods that are set to raise the bar for performance and reliability in the industry.The new range of cemented carbide rods from [Company Name] has been developed through intensive research and development, leveraging the latest advancements in materials science and manufacturing technology. The result is a product line that offers superior wear resistance, increased toughness, and enhanced thermal stability, making it suitable for even the most demanding applications.One of the key innovations in the new cemented carbide rods is the use of advanced coating technologies to further enhance their performance. By applying a proprietary coating to the surface of the rods, [Company Name] has been able to improve their resistance to heat and wear, extending their service life and reducing the need for frequent re-sharpening or replacement. This not only leads to cost savings for customers but also increases productivity by minimizing downtime for tool changes.Furthermore, the new cemented carbide rods from [Company Name] have been designed to provide exceptional dimensional accuracy and surface finish, ensuring that they can be machined with high precision and consistency. This makes them an ideal choice for the production of cutting tools, wear parts, and other components where tight tolerances and smooth surface finishes are critical.In addition to their outstanding mechanical properties, the new cemented carbide rods from [Company Name] are also environmentally friendly, featuring a composition that uses sustainable and responsibly sourced materials. This aligns with the company's commitment to sustainability and corporate social responsibility, ensuring that its products not only deliver exceptional performance but also adhere to the highest ethical and environmental standards.With the launch of its new line of cemented carbide rods, [Company Name] is positioning itself as a leader in the industry, offering a comprehensive range of solutions to meet the evolving needs of its customers. Whether it's for cutting, drilling, or forming challenging materials, businesses can rely on the superior quality and performance of [Company Name]'s cemented carbide rods to enhance their operations and achieve greater efficiency and productivity.As part of its commitment to customer satisfaction, [Company Name] also provides comprehensive technical support and application engineering services to help its clients optimize the performance of its cemented carbide rods in their specific operations. This includes assistance with tool selection, machining parameters, and troubleshooting, ensuring that customers can maximize the benefits of their investment in [Company Name]'s products.In conclusion, the launch of the new line of cemented carbide rods by [Company Name] marks a significant milestone in the industry, setting a new standard for performance, reliability, and sustainability. With its unwavering dedication to innovation and excellence, [Company Name] continues to solidify its position as a trusted partner for businesses seeking the highest quality solutions for their cutting, drilling, and shaping needs.

High-Quality Tungsten Carbide Drawing Plate for Industrial Applications

Tungsten Carbide Drawing Plate: The Epitome of High-Quality and Durable Industrial ToolsThe use of Tungsten Carbide Drawing Plates has revolutionized the industrial tool manufacturing industry, offering enhanced durability and performance. These drawing plates are essential components in the production of various industrial products, including wires, tubes, and rods. With their exceptional hardness and wear resistance, tungsten carbide drawing plates have become the top choice for manufacturers looking to achieve precision and efficiency in their operations.One prominent company that has been at the forefront of producing high-quality tungsten carbide drawing plates is [Company Name]. With a solid reputation for innovation and superior craftsmanship, [Company Name] has established itself as a leading supplier of industrial-grade tools and components. The company's dedication to excellence and its commitment to providing top-notch products have positioned them as a trusted partner for businesses across various industries.The production process of [Company Name]'s tungsten carbide drawing plates involves the use of advanced technology and high-quality materials. The result is a range of drawing plates that exhibit exceptional hardness, wear resistance, and strength, making them suitable for the most demanding industrial applications. These drawing plates are designed to withstand the rigors of continuous use, ensuring long-term reliability and performance for the end-users.In addition to their superior durability, [Company Name]'s tungsten carbide drawing plates are also known for their precise dimensions and smooth surface finish. This is crucial in the manufacturing of high-quality industrial products, as it allows for the production of consistent and accurate materials. The company's stringent quality control measures ensure that each drawing plate meets the highest standards, and customers can expect reliable and consistent performance from their products.[Company Name] takes pride in its ability to customize tungsten carbide drawing plates to meet specific requirements and applications. This flexibility allows the company to cater to the diverse needs of its customers, whether they are producing fine wires for electronics or heavy-duty rods for construction. With a focus on innovation and customer satisfaction, [Company Name] continues to push the boundaries of possibility in the industrial tool manufacturing industry.The use of tungsten carbide drawing plates has become integral to the success of many businesses, and [Company Name] plays a crucial role in meeting the growing demand for these essential components. By combining advanced manufacturing techniques, premium materials, and a dedication to excellence, [Company Name] has solidified its position as a go-to source for high-quality drawing plates and other industrial tools.As the industrial sector continues to evolve, the need for reliable and durable tools becomes increasingly important. Tungsten carbide drawing plates have proven to be indispensable in meeting these demands, and [Company Name] is poised to remain a key player in driving innovation and progress in the industry. With a proven track record of delivering top-notch products and a commitment to continuous improvement, [Company Name] stands as a beacon of excellence in the world of industrial tool manufacturing.

Discover the Efficiency and Durability of Cutting Tooth for Carbide Materials

Title: Innovative Carbide Cutting Tooth Revolutionizes Cutting Efficiency in Various IndustriesIntroduction:In today's rapidly evolving industries, the demand for efficient cutting tools that can withstand heavy workloads and offer superior performance has never been higher. Recognizing this pressing need, {Company Name}, a leading manufacturer of industrial tools, has introduced a groundbreaking Carbide Cutting Tooth. With its exceptional cutting prowess and durability, this advanced tool is set to transform the cutting processes across several sectors, including construction, mining, and forestry.Section 1: Evolution of Cutting ToolsThe field of cutting tools has experienced several evolutionary milestones, driven by the constant pursuit of improved performance and efficiency. Traditional cutting tools made of high-speed steel (HSS) have gradually been replaced by carbide-tipped alternatives due to their enhanced durability and wear resistance. Carbide, being a composite material of tungsten carbide particles embedded within a metallic binder, offers remarkable hardness and toughness necessary for heavy-duty operations.Section 2: Introducing the Innovative Carbide Cutting Tooth{Company Name} has utilized advanced research and development techniques to create a highly efficient Carbide Cutting Tooth that exceeds expectations. This innovative tool boasts a unique design, combining a trapezoidal shape with deep gullets, allowing for efficient chip evacuation during cutting operations, thus minimizing downtime and maximizing productivity.Section 3: Unparalleled Durability and LongevityOne of the key advantages of the Carbide Cutting Tooth is its unparalleled durability. The cutting edges incorporate high-quality carbide inserts, ensuring exceptional wear resistance even when subjected to extreme cutting conditions. This durability translates into reduced tool replacement and maintenance costs, ultimately boosting overall operational efficiency.Section 4: Enhanced Cutting PerformanceThe Carbide Cutting Tooth is engineered to deliver enhanced cutting performance across various materials. Whether cutting through concrete, wood, or metal, the advanced tooth design ensures precise cuts with reduced vibrations and increased stability. This cutting-edge technology facilitates smoother operations, resulting in superior finishing and reduced material wastage.Section 5: Application across IndustriesThe versatile Carbide Cutting Tooth finds applications in numerous industries. In construction, it offers significant advantages in road milling, trenching, and concrete demolition. In the mining sector, the tool exhibits exceptional performance in rock cutting and tunneling operations. Moreover, it proves valuable in the forestry industry for various applications, such as land clearing, tree felling, and branch trimming. Its widespread usage across these sectors demonstrates its adaptability and effectiveness.Section 6: Environmental Impact and Safety FeaturesIn line with the company's commitment to sustainability, the Carbide Cutting Tooth incorporates various safety features to minimize its environmental impact. High-efficiency chip evacuation mechanisms prevent dust and debris accumulation, reducing the release of harmful particles into the environment. Additionally, the cutting tooth design promotes operator safety by minimizing kickback and vibration, ensuring a secure working environment.Section 7: Market Outlook and ConclusionThe introduction of the innovative Carbide Cutting Tooth by {Company Name} is set to revolutionize the cutting tool market. Its superior cutting performance, exceptional durability, and versatility across industries make it the go-to choice for professionals seeking efficiency and reliability in their operations. With its potential to boost productivity, reduce costs, and improve overall cutting efficiency, this advanced tool is destined to be a game-changer for the global industry.In conclusion, the remarkable Carbide Cutting Tooth developed by {Company Name} signifies a significant leap in cutting tool technology. Its intelligent design, durability, and enhanced cutting performance are poised to transform cutting processes in construction, mining, and forestry sectors. As the demand for efficient cutting tools continues to soar, the industry is set to embrace this innovative solution that promises unparalleled efficiency, reduced costs, and improved overall outcomes.

High-Quality Nut Forming Die for Efficient Manufacturing

Nut Forming Die is a crucial tool used in the manufacturing industry for shaping and forming various types of nuts. It is a precision tool that is designed to create uniform and accurate nuts for use in a wide range of applications. With the increasing demand for high-quality nuts in the market, the need for efficient and reliable nut forming dies has also escalated.{Company} is a renowned manufacturer of precision tools and equipment for the manufacturing industry. With years of experience and a strong reputation for delivering top-notch products, {Company} has established itself as a leader in the field of precision tooling solutions. The company specializes in designing and producing a wide range of tools, including nut forming dies, to meet the diverse needs of its clients.The nut forming die manufactured by {Company} is known for its exceptional precision and durability. It is designed to withstand the rigors of high-volume manufacturing, ensuring consistent and reliable performance over time. The company utilizes advanced manufacturing techniques and high-quality materials to produce nut forming dies that meet the highest standards of quality and precision.One of the key features of the nut forming die produced by {Company} is its versatility. The die can be customized to create a wide range of nut shapes and sizes, making it a versatile tool for manufacturers across various industries. Whether it's for automotive, aerospace, or general manufacturing applications, the nut forming die from {Company} can be tailored to meet specific requirements, ensuring that manufacturers can produce nuts that meet their exact specifications.In addition to its exceptional performance, the nut forming die from {Company} is also designed for ease of use and maintenance. The company understands the importance of minimizing downtime and maximizing productivity in the manufacturing industry, which is why its nut forming dies are engineered for quick setup and tool changes. This allows manufacturers to streamline their production processes and improve overall efficiency.Furthermore, {Company} takes great pride in its commitment to customer satisfaction. The company works closely with its clients to understand their specific needs and deliver tailor-made solutions that meet and exceed expectations. Whether it's providing technical support, training, or ongoing maintenance, {Company} is dedicated to ensuring that its clients get the most out of their nut forming dies.With the growing demand for high-quality nuts in the market, {Company} is poised to play a crucial role in meeting the needs of manufacturers around the world. The company's commitment to excellence, combined with its expertise in precision tooling solutions, makes it a trusted partner for companies looking to enhance their manufacturing capabilities.In conclusion, the nut forming die from {Company} is a superior tool that offers exceptional precision, versatility, and reliability. With its advanced design and engineering, the die is well-equipped to meet the diverse needs of manufacturers across various industries. As the demand for high-quality nuts continues to rise, {Company} is well-positioned to provide the tools and support that manufacturers need to thrive in a competitive market.

High-Quality Tungsten Carbide Strips for Industrial Use

Tungsten Carbide Strips: The Future of Advanced ManufacturingIn the ever-evolving landscape of advanced manufacturing, the demand for high-performance materials and cutting-edge technology continues to drive the industry forward. Tungsten carbide, a renowned material known for its exceptional hardness and toughness, has been the go-to choice for a wide range of industrial applications. With the introduction of YG15 Tungsten Carbide Strips, the game is about to change even more.The YG15 Tungsten Carbide Strips, developed by a leading manufacturing company specializing in top-of-the-line carbide products, are designed to meet the demanding requirements of modern manufacturing processes. The strips are meticulously engineered to deliver superior performance, reliability, and longevity, making them an ideal choice for a variety of applications, from metal cutting and wear parts to mining and drilling operations.With a composition of 85% tungsten carbide and 15% cobalt, the YG15 strips boast exceptional hardness and strength, enabling them to withstand extreme conditions and heavy-duty usage. This makes them the perfect solution for industries that require high-performance tools and components that can endure challenging environments and rigorous applications.Moreover, the YG15 Tungsten Carbide Strips are precision ground to tight tolerances, ensuring consistent and uniform dimensions for seamless integration into manufacturing processes. This meticulous attention to detail not only enhances the performance of the strips but also contributes to the overall efficiency and quality of the end products.One of the key advantages of the YG15 Tungsten Carbide Strips is their exceptional wear resistance, which significantly extends the service life of tools and components. This translates to reduced downtime, lower maintenance costs, and increased productivity, making them a cost-effective solution for businesses looking to improve their bottom line.In addition to their impressive mechanical properties, the YG15 Tungsten Carbide Strips are also highly resistant to corrosion, chemicals, and high temperatures, further expanding their potential applications across a wide spectrum of industries. Whether it's cutting, shaping, drilling, or grinding, these strips offer unparalleled performance and reliability, making them a valuable asset for manufacturers worldwide.It's worth noting that the company behind the YG15 Tungsten Carbide Strips has a rich history in the carbide industry, with a proven track record of delivering innovative solutions and exceptional products to its customers. Their state-of-the-art manufacturing facilities, advanced quality control processes, and team of experienced professionals ensure that every product meets the highest standards of excellence.Furthermore, the company's commitment to research and development continuously drives the evolution of their products, keeping them at the forefront of technological advancements in the carbide industry. This unwavering dedication to innovation and improvement sets them apart as a trusted partner for businesses seeking cutting-edge solutions for their manufacturing needs.As the demand for high-performance materials and advanced manufacturing solutions continues to grow, the YG15 Tungsten Carbide Strips stand poised to make a significant impact in the industry. With their exceptional properties, precision engineering, and proven reliability, these strips represent the future of advanced manufacturing, empowering businesses to achieve new levels of efficiency, productivity, and success.