| Grade | Density | T.R.S | Hardness | Performance & Application Recommended |

| g/cm3 | MPα | HRA | ||

| YG6 | 14.9 | 2100 | 90 | or coring crowns,electric coal drill bits,coal cutting picks,oil cone bits and scraping knife bits, usd in geological prospecting, coal mining and oil well boring. |

| YG8 | 14.7 | 2400 | 89.5 | For coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

| YG8C | 14.7 | 2450 | 88.5 | Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

| YG9C | 14.6 | 2450 | 87.8 | Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations. |

| YG10C | 14.4 | 2550 | 87 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

| YG11C | 14.4 | 2600 | 87 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

| YG13C | 14.2 | 2650 | 86.5 | Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. |

| YG15C | 14 | 2700 | 86.5 | For oil cone drill bits, for medium soft and medium -hard rocks. |

| YG15 | 14 | 2500 | 87.5 | Good strength and less wear resistance,for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. |

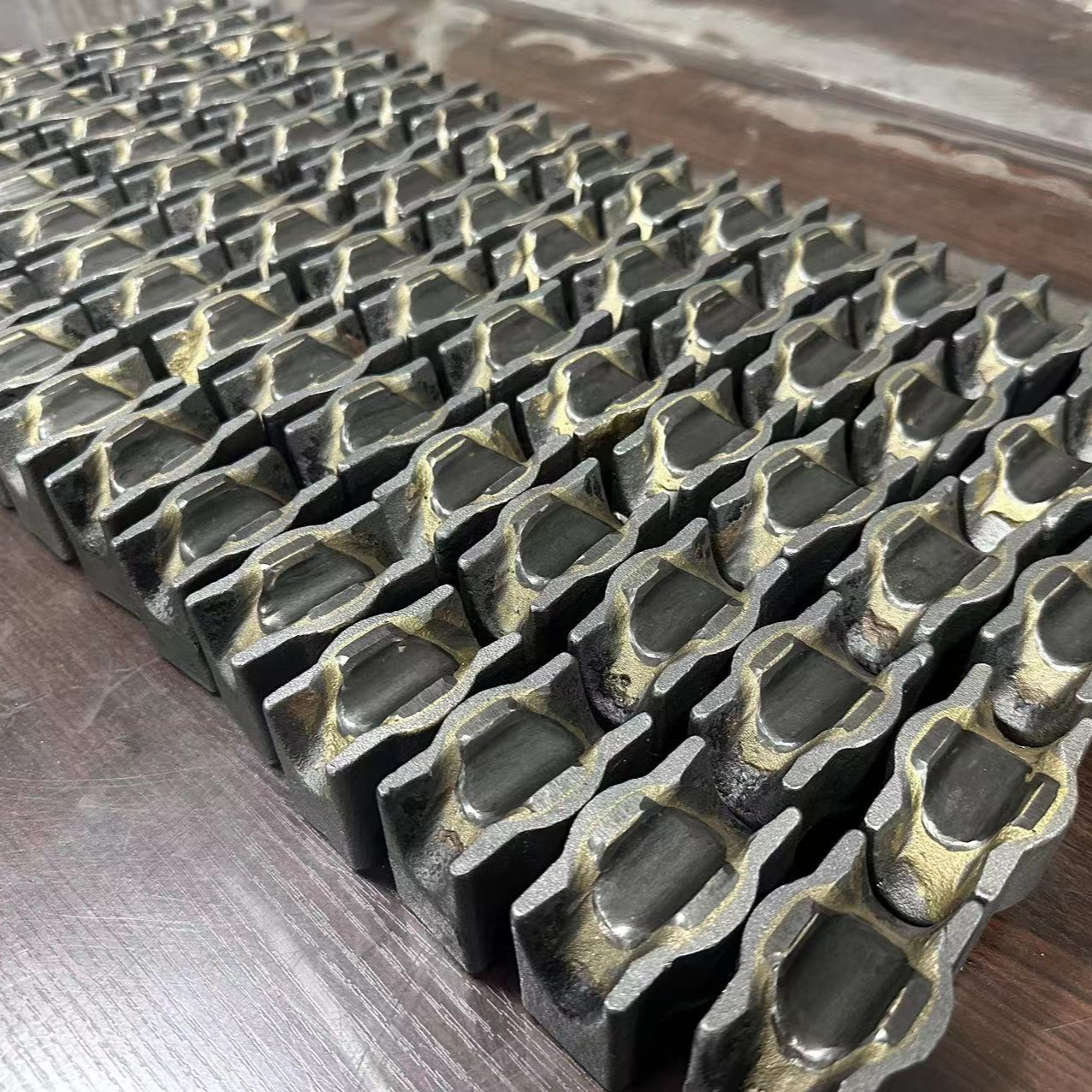

YG15 Milling Pr Ro Rt Fo Size Tungsten Carbide Roller Cold Rolling Longlife

Shop our high-quality YG15 Milling Pr Ro Rt Fo Size Tungsten Carbide Roller Cold Rolling Longlife products. As a factory, we guarantee reliability and durability.

Request a QuotePRODUCTS DETAILS

Hot Products

High quality and competitive price TC rings/tungsten carbide roller

Tungsten Carbide Standard Ring Roller

15% Cobalt YG15 Tungsten Carbide Cold Heading Dies For Cold Heading Machine

Tungsten carbide cold heading die for punching mould tool parts

Factory price Tungsten Carbide Roll Ring Made in China Roller Ring

Factory price high specific gravity tungsten alloy High-density tungsten carbide dies

High Hardness Tungsten Carbide Straightening Block Die For Straightening Steel Wire

Cheap YG8 Tungsten Carbide Wear-Resistance Parts

Screw Second Punch Dies Punch Pin Cold Heading Machine Dies

Tungsten Carbide Brazed Nail Cutter Wire Nail Cutting Set Tools for Nail Making

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours