Top Qualities to Look for in Cemented Carbide Cutting Tips

By:Admin

Introduction:

[Company Name], a leading pioneer in the manufacturing industry, continues to surge ahead with groundbreaking innovations in cutting edge technology. With a commitment to providing the highest quality products, the company has introduced its latest creation - Cemented Carbide Cutting Tips. These advanced cutting tips are set to revolutionize precision and efficiency in manufacturing processes across various industries.

Unparalleled Quality:

[Company Name] has always been synonymous with quality and reliability. The Cemented Carbide Cutting Tips are no exception. These cutting tips are manufactured using the finest quality raw materials and state-of-the-art technology, ensuring durability, accuracy, and consistent performance. The company's stringent quality control measures at every stage of production guarantee that each cutting tip meets the highest industry standards.

Enhanced Precision:

Precision is crucial in the manufacturing industry, and any improvement in accuracy can yield significant gains for producers. Cemented Carbide Cutting Tips excel in this aspect, offering enhanced precision to manufacturers. The tips are meticulously crafted, utilizing proprietary techniques that result in incredibly sharp and resilient cutting edges. This precision allows for tighter tolerances and smoother finishes, greatly reducing the need for additional manual finishing processes.

Increased Efficiency:

Manufacturers are constantly seeking ways to streamline their processes and optimize efficiency. Cemented Carbide Cutting Tips offer a solution to this perennial challenge. By virtue of their exceptional wear resistance and toughness, these tips deliver prolonged tool life, reducing the frequency of tool changes. This translates to lowered downtime, increased productivity, and substantial cost savings for manufacturers.

Versatility across Applications:

[Company Name]'s Cemented Carbide Cutting Tips have been designed to cater to a wide range of manufacturing needs. From precision engineering to automotive and aerospace industries, these cutting tips exhibit remarkable adaptability. Seamless machining of various materials, including steel, cast iron, stainless steel, and non-ferrous metals, is effortlessly achieved, ensuring reduced tool inventory and simplified production processes.

Environmental Sustainability:

In addition to their outstanding performance, Cemented Carbide Cutting Tips align with the growing need for environmentally sustainable manufacturing practices. By reducing the frequency of tool changes, these tips contribute to minimization of waste generation. Furthermore, the company's commitment to eco-friendly processes ensures that the manufacturing of these tips adheres to stringent ecological standards.

Future Outlook:

With the introduction of Cemented Carbide Cutting Tips, [Company Name] has solidified its position as a leading innovator in the manufacturing industry. The company's commitment to research and development, coupled with its relentless pursuit of excellence, has enabled the creation of a cutting-edge product that sets the bar high for competitors.

[Company Name] remains steadfast in its dedication to providing the manufacturing industry with cutting-edge tools that enhance precision, efficiency, and sustainability. As the industry continues to evolve, [Company Name] will continue to drive progress and shape the future of manufacturing with its innovative solutions.

Conclusion:

Through the introduction of Cemented Carbide Cutting Tips, [Company Name] has once again established itself as an industry leader in providing innovative solutions for precision machining. The advanced technology and impeccable quality of these cutting tips are set to revolutionize manufacturing processes across various industries, offering unparalleled precision, increased efficiency, and environmental sustainability. As [Company Name] continues its commitment to pushing boundaries in the manufacturing industry, the future certainly looks promising for manufacturers seeking the ultimate edge in precision cutting.

Company News & Blog

The Latest News About High-Quality Tungsten Carbide Rings

Tungsten Carbide Rings: The Ultimate Symbol of Love and StrengthWedding rings are one of the most essential part of a wedding ceremony that symbolizes love, commitment and loyalty towards each other. It is not only a piece of jewelry, rather a sentiment that you wear around your finger and cherish for the rest of your life. With various alternatives available, couples are now opting for tungsten carbide rings instead of traditional gold or platinum bands. Its unique nature, unparalleled durability and its lower price point are some of the reasons why it has become the preferred choice for couples around the world.Tungsten carbide rings are made by combining tungsten with carbon atoms, which creates a tough and durable material, resistant to wear and tear. Due to its resistance to scratching, fading, and damage, it is the perfect choice for a wedding band. These rings are made using advanced technology, which allows for intricate designs and engravings, which makes each ring unique. Tungsten carbide rings have a masculine and classic look, perfect for both men and women.There are many advantages of choosing tungsten carbide rings over traditional metals like gold or platinum. Firstly, it is much more durable. It can withstand day-to-day wear and tear, and is resistant to scratches and damage. Which means, the ring will look just as good years after your wedding day. Secondly, tungsten carbide rings are hypoallergenic which means they are ideal for those who have sensitive skin allergies. Thirdly, it is available at a lower price point when compared to gold or platinum, without compromising on its unique look and strength. Additionally, tungsten carbide rings can be customized to any pattern, finish or color which provides the perfect opportunity to add a personal touch to your wedding ring.For couples looking to purchase tungsten carbide rings, one brand that stands out is {}. The company has been in existence for over 16 years and has perfected the art of designing and manufacturing tungsten carbide rings. Their focus on quality and precision has made them one of the leading providers of tungsten carbide rings. In addition to traditional wedding bands, the brand offers a range of tungsten carbide engagement rings that come in a variety of styles, finishes and colors, the perfect choice to express your love and commitment to your partner.In addition to its traditional designs, {} takes it up a notch with its specially curated collections designed for couples who want their rings to stand out. The Black Collection, a favorite among couples who are looking for a more contemporary design, features a black tungsten carbide finish with rose gold or silver accents. The Carbon Collection, on the other hand, features a combination of black and silver tungsten carbide with carbon fiber inlays, providing a sleek and modern edge. The Infinity Collection, with its signature infinity symbol, is a reminder of the eternal love and commitment between two individuals.At {}, the mission is to provide couples with a symbol of love and strength that lasts a lifetime. In addition to providing the perfect wedding band, the brand also offers engraving services that add a personalized touch to the ring. {} strives to exceed expectations by providing exceptional customer service, making the journey of selecting a wedding band a memorable one.Tungsten carbide rings are the perfect choice for couples looking for a wedding band that is unique, durable and affordable. {} provides a range of options that is sure to surpass all expectations. The collection of tungsten carbide rings offered by the brand is designed to cater to different personalities and styles, ensuring that each couple finds the perfect match. With a focus on quality, precision and customer service, {} has become the go-to destination for couples looking for the ultimate symbol of love and strength.

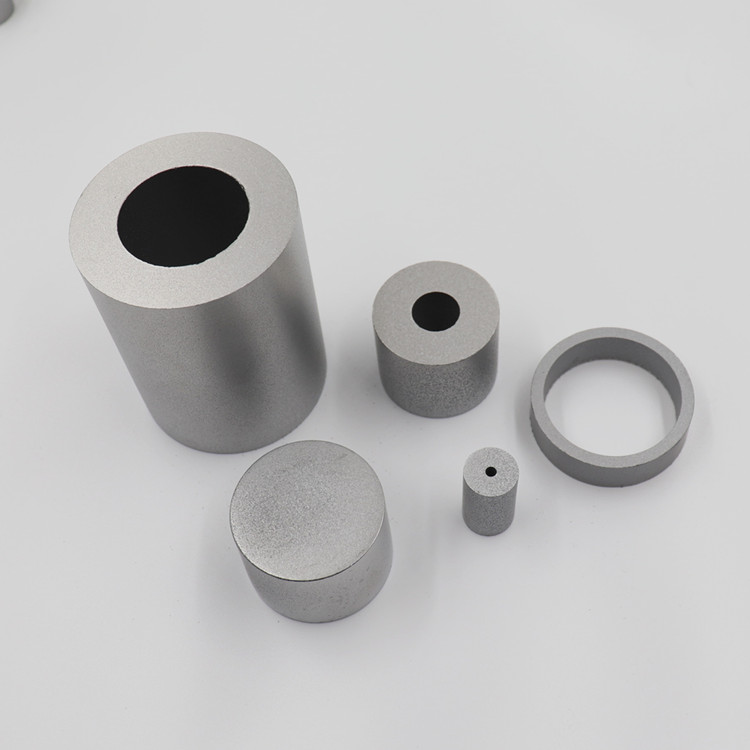

Tungsten Carbide Block: A Valuable Industrial Material for Various Applications

Tungsten Carbide Block Emerges as a Game-Changer in the Manufacturing IndustryTungsten carbide is a compound that combines tungsten and carbon, making it a highly versatile material for manufacturing a variety of products. The tough and durable nature of tungsten carbide makes it one of the most preferred materials for applications that require long durability, such as machine parts.Recent technological advancements in the manufacturing industry have given birth to a new product - the tungsten carbide block. These blocks, made from high-quality tungsten carbide, have become a game-changer in the manufacturing industry, as they offer unique properties that traditional materials cannot match.Tungsten carbide blocks are used in various industries, including construction, mining, and manufacturing. They have a wide range of applications that require high wear and abrasion resistance, such as manufacturing cutting tools, dies, and punches. These blocks offer superior performance and longevity compared to other carbide-based materials, making them the leading choice for toolmakers and manufacturers alike.One of the main advantages of tungsten carbide blocks is their ability to withstand high temperatures. The material has a high melting point, making it an ideal choice for applications that require high resistance to heat. Tungsten carbide blocks are also highly resistant to deformation, making them suitable for use in high-pressure environments.Additionally, tungsten carbide blocks exhibit exceptional hardness, providing high wear resistance, and low friction. This unique combination of properties makes the carbide block ideal for applications that require high-precision machining. Many industries, such as the oil and gas and mining sectors, have adopted tungsten carbide blocks due to their outstanding performance in harsh environments.Leading tungsten carbide block manufacturers pride themselves in producing exceptional quality blocks. They focus on using only the best raw materials and state-of-the-art technology to ensure that their blocks meet the most stringent quality standards. This quality-oriented approach has enabled manufacturers to remain the go-to source for manufacturers seeking high-quality tungsten carbide blocks.Tungsten carbide blocks come in different shapes and sizes, catering to various manufacturing applications. Manufacturers can order customized blocks tailored to their specific needs, with varying grades of tungsten carbide to suit the specific application. Additionally, manufacturers can request blocks with different surface finishes to enhance their resistance to wear and corrosion.The growing demand for tungsten carbide blocks has prompted many companies to invest in advanced technology to streamline their production processes. These investments have enabled manufacturers to produce tungsten carbide blocks faster without compromising on quality. Automation has also helped manufacturers to reduce production costs while improving their output.The adoption of tungsten carbide blocks has revolutionized the manufacturing industry, providing manufacturers with cutting-edge technology that improves production performance, longevity, and accuracy. Manufacturers in various industries now have access to a broad range of options to choose from, ensuring that they get the precise block they need for their specific applications.Moreover, by using tungsten carbide blocks, manufacturers can enhance their bottom lines by reducing their production costs and improving the quality of their products. Tungsten carbide blocks are a superior material that is cost-effective in the long run, making them an ideal choice for manufacturers who seek to maximize their profits.The future of tungsten carbide blocks looks bright, with increased investments in R&D that continue to enhance their quality, performance, and durability. Manufacturers can expect to see more advanced products that push the limits of what tungsten carbide blocks can offer.In conclusion, tungsten carbide blocks are a highly durable and versatile material that has revolutionized the manufacturing industry. With their exceptional strength, heat resistance, and wear resistance, these blocks continue to be a game-changer in many industries, providing manufacturers with a cost-effective solution that enhances their performance and bottom line. As the industry continues to invest in advanced technology, manufacturers can expect to benefit from even more innovative tungsten carbide blocks.

Discover the Key Benefits of Tungsten Carbide Bushing Die According to the Latest News

Tungsten Carbide Bushing Die (need remove brand name) Is The Leading Choice For Precision ManufacturingWith over 20 years of experience in the tungsten carbide industry, (brand name) has become the leading provider of precision machining solutions for customers in various industries. The company specializes in producing high-performance tungsten carbide bushing dies that can help improve production efficiency and reduce costs.Tungsten carbide is a powerful and durable material that can withstand high temperatures and pressure. It is ideal for use in precision machining because of its hardness and strength, making it the perfect choice for dies in the manufacturing process. When combined with steel, tungsten carbide provides a unique blending that combines toughness and wear resistance with the ability to retain sharp cutting edges.The tungsten carbide bushing dies offered by (brand name) are designed to deliver consistent performance even in the most challenging environments. These bushing dies are commonly used in the production of wire and cable, rubber and plastics, and metalworking industries. With their high resistance to wear and superior accuracy, these dies ensure that products meet the exacting standards of customers and end-users.(brand name) specializes in producing bushing dies that can be customized to meet specific customer requirements. The company has a team of experienced engineers who use advanced CAD/CAM software to create high-precision tooling that is tailored to individual customer needs. The company's dies are used by customers around the world, including China, the United States, and Europe.The tungsten carbide bushing dies produced by (brand name) have several advantages over traditional steel or ceramic dies. Tungsten carbide is much more durable than steel, making it less prone to wear and tear. It is also more resistant to corrosion and can withstand extreme temperatures and pressures. This means that tungsten carbide dies last longer and require less maintenance than other materials.Another advantage of tungsten carbide is its high coefficient of friction. This means that less lubrication is required during the manufacturing process, reducing overall costs. Additionally, tungsten carbide dies require less power to operate than other materials, reducing energy costs and improving efficiency.The quality of tungsten carbide bushing dies can significantly impact an organization's productivity and profitability. With over two decades of experience in the industry, (brand name) has become the leading provider of high-quality, precision tungsten carbide machining solutions. The company's dedication to providing customized products and exceptional customer service has made it a trusted partner to organizations around the world.In conclusion, the tungsten carbide bushing dies produced by (brand name) are an essential component of precision machining processes used by leading manufacturers globally. The company's commitment to quality and service has made it the first choice for customers in various industries. With its team of experienced engineers and advanced production capabilities, (brand name) is well-positioned to continue leading the industry in the production of high-performance tungsten carbide bushing dies.

Cemented Carbide Pallets: A Leading Solution for Durable Industrial Applications

Title: Innovative Cemented Carbide Pallets Revolutionize Industrial ApplicationsIntroduction:In the constantly evolving landscape of industrial tools and materials, cemented carbide pallets have emerged as a game-changer. These exceptionally durable and versatile tools have gained immense popularity for their ability to withstand extreme conditions, enhance productivity, and improve manufacturing processes across various industries.Company Introduction:{Company Name} is a renowned leader in the development and production of cemented carbide pallets. With years of experience and a proven track record of delivering high-quality solutions, {Company Name} has established itself as a trusted provider of innovative tools for diverse industrial applications. Combining cutting-edge technology, meticulous research, and a commitment to excellence, {Company Name} continues to set new benchmarks in the manufacturing industry.[Paragraph 1 - Cemented Carbide Pallets Overview]Cemented carbide pallets, also known as hard metal pallets, are manufactured from a combination of metal carbide and binder metals. This unique composition results in a superior material that is incredibly resistant to wear, corrosion, and heat. The exceptional strength and hardness of these pallets make them ideal for use in a wide range of industrial applications where traditional tools fall short.[Paragraph 2 - Unmatched Durability]One of the key features that sets cemented carbide pallets apart from conventional tools is their unparalleled durability. Thanks to their exceptional hardness, these pallets can withstand extreme conditions and abrasive materials without losing their effectiveness. They can endure high temperatures, heavy impacts, pressure, and exposure to corrosive agents, ensuring robust performance and prolonged tool life.[Paragraph 3 - Enhanced Productivity]With cemented carbide pallets, industries can optimize their efficiency and maximize productivity. The superior hardness and wear resistance of these pallets eliminate the need for frequent tool changes, reducing downtime and increasing operational speed. This results in improved manufacturing processes and significant cost savings, making cemented carbide pallets a preferred choice for various industries, including automotive, aerospace, mining, and manufacturing.[Paragraph 4 - Versatile Applications]The versatility of cemented carbide pallets is another aspect that makes them invaluable to industries. These pallets are available in a range of shapes and sizes, tailored to meet the specific requirements of different machining operations. From cutting, drilling, and shaping to grinding and milling, cemented carbide pallets can handle a variety of tasks with precision. Their exceptional performance in tooling applications enables industries to achieve greater accuracy and finer finishes.[Paragraph 5 - Sustainability]In addition to their remarkable performance, cemented carbide pallets contribute to sustainable manufacturing. The long lifespan of these pallets reduces waste generated from frequent tool replacements, minimizing the environmental impact. Furthermore, their improved efficiency and reduced energy consumption significantly lower carbon emissions during the manufacturing process. By opting for cemented carbide pallets, industries can align their operations with sustainable practices and contribute to a greener future.[Paragraph 6 - Ongoing research and development]{Company Name} recognizes the importance of continuous innovation and investment in research and development. Committed to staying ahead of the curve, the company consistently explores new materials, advanced manufacturing techniques, and improved designs for cemented carbide pallets. This ensures that their customers always have access to the latest technologies and solutions to address their evolving needs and challenges.[Paragraph 7 - Conclusion]Cemented carbide pallets have revolutionized the industrial landscape, offering exceptional durability, enhanced productivity, versatility, and sustainability. With {Company Name} leading the way in their development and production, industries can embrace these innovative tools to optimize their processes and achieve unprecedented results. As the demand for reliable and high-performance tools continues to grow, cemented carbide pallets are set to become an indispensable asset across a myriad of industries, driving progress and shaping the future of manufacturing.

Discover the Superiority of Tungsten Carbide Rings - YG11

Tungsten carbide rings have been a popular choice for wedding bands and fashion accessories in recent years. Known for their durability, scratch resistance, and affordability, tungsten carbide rings have become a go-to option for couples looking to tie the knot.However, not all tungsten carbide rings are created equal. There are many different grades of tungsten carbide, each with their own unique properties and characteristics. The YG11 tungsten carbide ring, for example, is one of the highest quality tungsten carbide rings on the market.Designed and manufactured by a leading jewelry manufacturer (company name) based in China, the YG11 tungsten carbide ring is made using only the finest materials and craftsmanship. The company has over 20 years of experience in producing high-quality jewelry products, from wedding bands to fashion accessories, and is known for its commitment to quality and attention to detail.What sets the YG11 tungsten carbide ring apart from other tungsten carbide rings on the market is its superior hardness and strength. The YG11 grade of tungsten carbide is one of the hardest materials available, second only to diamond. This means that the YG11 tungsten carbide ring is virtually scratch-proof and will not bend or warp under normal wear and tear.In addition to its durability, the YG11 tungsten carbide ring is also hypoallergenic, making it a great option for anyone with sensitive skin. The ring is also highly resistant to corrosion and tarnishing, ensuring that it will maintain its shine and luster for years to come.Another advantage of the YG11 tungsten carbide ring is its versatility. The ring can be customized with a variety of finishes and designs, from classic polished and brushed finishes to more intricate and unique designs. The company offers a range of styles, from simple and understated to bold and eye-catching, ensuring that there is a YG11 tungsten carbide ring to suit every personal style and preference.Overall, the YG11 tungsten carbide ring is an excellent choice for anyone looking for a high-quality, durable, and stylish ring. With its superior strength, scratch resistance, and versatility, the YG11 tungsten carbide ring is sure to become a treasured piece of jewelry that will last for years to come.

Top 5 Durable and Efficient Tools for Your Workshop

[Company Name] Introduces Superior Tungsten Carbide Tools for Enhanced Efficiency and Productivity[City name, Date] - [Company Name], a leading manufacturer of cutting-edge industrial tools, has unveiled its latest line of premium-quality tungsten carbide tools. Leveraging its extensive expertise in tool manufacturing, the company aims to cater to the increasing demand for high-performance tools in diverse industries.With a strong commitment to delivering innovative solutions, [Company Name] has invested significant resources into research and development, resulting in the creation of state-of-the-art tungsten carbide tools. These tools are designed to not only enhance efficiency and productivity but also deliver unparalleled precision and durability.Tungsten carbide is a compound known for its exceptional hardness and resistance to wear and tear, making it an ideal material for tool manufacturing. By combining tungsten carbide with other sophisticated alloys, [Company Name] has created a wide range of tools suitable for various applications, including cutting, drilling, grinding, and milling.One of the key highlights of [Company Name]'s tungsten carbide tools is their exceptional cutting-edge retention. Unlike conventional tools, which often need frequent sharpening, these tools possess remarkable wear resistance, extending their lifespan and reducing downtime significantly. This advantage allows businesses to optimize their operations and streamline their production processes.Additionally, the advanced composition of [Company Name]'s tungsten carbide tools provides increased heat resistance, allowing for higher operating speeds. This feature leads to faster production cycles and higher throughput, resulting in improved overall efficiency. Furthermore, the enhanced heat resistance decreases the risk of tool deformation, ensuring consistent and reliable performance over prolonged periods.The versatility of [Company Name]'s tungsten carbide tools enables them to cater to a wide range of industries, including automotive, aerospace, construction, and mining. From precision cutting tools used in the automotive industry to heavy-duty tools required for mining operations, [Company Name] offers a comprehensive selection to meet various industrial needs.In addition to their durability and reliability, [Company Name]'s tungsten carbide tools are also designed for ease of use and operator comfort. Ergonomics are considered during the tool design process, ensuring that workers can handle the tools efficiently and safely for prolonged periods.To meet diverse customer requirements, [Company Name] offers customization options for its tungsten carbide tools. The company's team of experienced engineers works closely with clients to understand their specific needs and develops tailor-made solutions. This personalized approach sets [Company Name] apart from its competitors, as it strives to deliver customer-centric products and services.Furthermore, [Company Name] maintains a robust distribution network, ensuring that its tungsten carbide tools are readily available to customers worldwide. Alongside providing high-quality tools, the company offers comprehensive technical support and after-sales services to ensure customer satisfaction at every stage.Speaking about the latest product line, [Name], [Company Name]'s spokesperson, highlighted the company's commitment to innovation and customer success. He stated, "We are excited to introduce our new range of tungsten carbide tools that reflect our dedication to providing cutting-edge solutions to our customers. Through continuous research and development, we have created tools that not only meet but exceed industry standards, enabling our clients to achieve enhanced productivity and efficiency."With its innovative range of tungsten carbide tools, [Company Name] is poised to revolutionize the industrial tooling landscape. As businesses increasingly recognize the importance of utilizing high-performance tools, [Company Name] stands ready to meet their needs, ensuring they stay ahead in today's competitive market.About [Company Name]:[Company Name] is a renowned manufacturer of industrial tools with a strong focus on innovation and customer satisfaction. With a global presence, the company serves diverse industries, delivering cutting-edge solutions and exceptional customer service. Through continuous research and development, [Company Name] aims to set new standards in the tool manufacturing industry.

Cemented Carbide Rods: Durable Tools for Various Industries

Cemented Carbide Rods - Providing High-Quality Performance and DurabilityCemented Carbide Rods are an essential tool in the manufacturing industry. These high-performance components are made from a combination of tungsten carbide and cobalt, which makes them incredibly durable and resistant to wear. They are used to cut, shape, or drill different materials to produce a wide range of products.One company that has been at the forefront of producing high-quality cemented carbide rods is {name of company}. The company has been in operation for many years and has gained a reputation as a leader in the manufacturing of carbide tools. The company's success can be attributed to its state-of-the-art manufacturing processes, excellent customer service, and commitment to producing high-quality products.Cemented carbide rods are used in a variety of industries, including mining, construction, automotive, and aerospace. These industries demand high-performance and durable tools that can withstand the harsh environments they work in. Carbide rods are an ideal choice because they are made from a combination of tungsten carbide and cobalt, which makes them highly resistant to wear and corrosion.The manufacturing process of cemented carbide rods involves several stages, including powder preparation, pressing, presintering, sintering, and finishing. {name of company} uses advanced technology and state-of-the-art machinery to ensure that every step of the process is done correctly, resulting in high-quality products. The company's production line can produce a range of rod sizes and lengths to meet customer requirements.One unique feature of {name of company}'s cemented carbide rods is that they are available in different grades. The company offers standard grades, which are ideal for general machining applications, and special grades that are designed for specific applications. The special grades are tailored to meet the demands of specific industries, resulting in higher efficiency and productivity.In addition to producing high-quality cemented carbide rods, {name of company} also offers other carbide tools, including end mills, drill bits, and inserts. The company's product range is extensive, ensuring that customers can find the right tool for their application. The company also offers customized solutions for customers who have specific requirements or special applications.Customer service is a top priority for {name of company}, and the company has a team of experts who provide technical support and advice to customers. The team can help customers choose the right tool for their application and provide recommendations on how to optimize their machining processes. The company's commitment to customer service has helped it gain a loyal customer base, with many customers returning to purchase more products.In conclusion, cemented carbide rods are an essential tool in the manufacturing industry, and {name of company} has established itself as a leader in the production of high-quality carbide tools. The company's commitment to producing high-quality products, using advanced technology and state-of-the-art machinery, has resulted in products that are highly durable, resistant to wear, and ideal for demanding applications. The company's extensive product range, coupled with its commitment to customer service, has made it a preferred choice among many customers.

Top Qualities to Look for in Cemented Carbide Cutting Tips

Title: Innovations in Carbide Cutting Tips: Revolutionizing Precision and Efficiency in ManufacturingIntroduction:[Company Name], a leading pioneer in the manufacturing industry, continues to surge ahead with groundbreaking innovations in cutting edge technology. With a commitment to providing the highest quality products, the company has introduced its latest creation - Cemented Carbide Cutting Tips. These advanced cutting tips are set to revolutionize precision and efficiency in manufacturing processes across various industries.Unparalleled Quality:[Company Name] has always been synonymous with quality and reliability. The Cemented Carbide Cutting Tips are no exception. These cutting tips are manufactured using the finest quality raw materials and state-of-the-art technology, ensuring durability, accuracy, and consistent performance. The company's stringent quality control measures at every stage of production guarantee that each cutting tip meets the highest industry standards.Enhanced Precision:Precision is crucial in the manufacturing industry, and any improvement in accuracy can yield significant gains for producers. Cemented Carbide Cutting Tips excel in this aspect, offering enhanced precision to manufacturers. The tips are meticulously crafted, utilizing proprietary techniques that result in incredibly sharp and resilient cutting edges. This precision allows for tighter tolerances and smoother finishes, greatly reducing the need for additional manual finishing processes.Increased Efficiency:Manufacturers are constantly seeking ways to streamline their processes and optimize efficiency. Cemented Carbide Cutting Tips offer a solution to this perennial challenge. By virtue of their exceptional wear resistance and toughness, these tips deliver prolonged tool life, reducing the frequency of tool changes. This translates to lowered downtime, increased productivity, and substantial cost savings for manufacturers.Versatility across Applications:[Company Name]'s Cemented Carbide Cutting Tips have been designed to cater to a wide range of manufacturing needs. From precision engineering to automotive and aerospace industries, these cutting tips exhibit remarkable adaptability. Seamless machining of various materials, including steel, cast iron, stainless steel, and non-ferrous metals, is effortlessly achieved, ensuring reduced tool inventory and simplified production processes.Environmental Sustainability:In addition to their outstanding performance, Cemented Carbide Cutting Tips align with the growing need for environmentally sustainable manufacturing practices. By reducing the frequency of tool changes, these tips contribute to minimization of waste generation. Furthermore, the company's commitment to eco-friendly processes ensures that the manufacturing of these tips adheres to stringent ecological standards.Future Outlook:With the introduction of Cemented Carbide Cutting Tips, [Company Name] has solidified its position as a leading innovator in the manufacturing industry. The company's commitment to research and development, coupled with its relentless pursuit of excellence, has enabled the creation of a cutting-edge product that sets the bar high for competitors.[Company Name] remains steadfast in its dedication to providing the manufacturing industry with cutting-edge tools that enhance precision, efficiency, and sustainability. As the industry continues to evolve, [Company Name] will continue to drive progress and shape the future of manufacturing with its innovative solutions.Conclusion:Through the introduction of Cemented Carbide Cutting Tips, [Company Name] has once again established itself as an industry leader in providing innovative solutions for precision machining. The advanced technology and impeccable quality of these cutting tips are set to revolutionize manufacturing processes across various industries, offering unparalleled precision, increased efficiency, and environmental sustainability. As [Company Name] continues its commitment to pushing boundaries in the manufacturing industry, the future certainly looks promising for manufacturers seeking the ultimate edge in precision cutting.

Tungsten Carbide Brazing Tips: A Comprehensive Guide for Effective Bonding

Tungsten Carbide Brazing Tips Revolutionize Welding IndustryAs the demand for high-quality and durable welding solutions continues to rise, manufacturers worldwide are constantly striving to develop state-of-the-art products that can meet the ever-evolving needs of the industry. In line with this goal, an industry-leading company introduces its innovative Tungsten Carbide Brazing Tips, a game-changer that is set to revolutionize the welding industry.Welders are no strangers to the challenges associated with finding the perfect brazing tips. The traditional options available often suffer from issues such as poor durability, reduced performance, and high replacement costs. However, this company has taken a leap forward by developing brazing tips made from Tungsten Carbide, a cutting-edge material that promises to overcome these challenges.Tungsten Carbide is a remarkable compound known for its exceptional hardness, superior durability, and resistance to wear and tear. Its ability to withstand high temperatures and provide a consistently strong performance makes it an ideal choice for brazing tips, enabling welders to achieve precise and efficient results with ease.One of the key features of this innovative product is its longevity. Unlike traditional brazing tips that wear out quickly and require frequent replacement, Tungsten Carbide Brazing Tips are built to last. This offers significant cost savings for welders as they can enjoy prolonged usage without worrying about the added expenses of constantly purchasing new tips.Additionally, the outstanding performance of these brazing tips ensures greater efficiency and improved results. The hardness of Tungsten Carbide enhances its resistance to wear and tear, allowing welders to work on a wide range of materials without compromising the quality of their work. This product's exceptional durability also contributes to reducing downtime, as welders can continue their work uninterrupted for longer periods.Furthermore, the Tungsten Carbide Brazing Tips offer enhanced precision and accuracy during welding. The high melting point and excellent heat resistance properties of Tungsten Carbide minimize tip deformation, resulting in better control and finer welds. This newfound precision empowers welders to complete their projects with meticulousness and expertise, thus satisfying even the most demanding industry standards.The company behind this groundbreaking product has built a reputation for innovative solutions and unparalleled expertise in the welding industry. Their commitment to research and development has enabled them to stay ahead of the curve, continuously introducing cutting-edge products that redefine industry standards.With a dedicated team of experts, the company ensures that every aspect of their product development process is meticulously planned and executed. From the selection of premium raw materials to the utilization of state-of-the-art manufacturing techniques, they leave no stone unturned in their pursuit of excellence. Their stringent quality control measures guarantee that each Tungsten Carbide Brazing Tip is built to last, providing welders with the utmost reliability and performance.Looking ahead, the introduction of Tungsten Carbide Brazing Tips is poised to have a significant impact on the welding industry. This breakthrough product not only addresses the common issues faced by welders but also raises the bar for what can be achieved through cutting-edge technology and innovation.Welders around the world can now take advantage of these remarkable tips to enhance their performance, improve their efficiency, and deliver impeccable results. The Tungsten Carbide Brazing Tips are set to become an indispensable component in every welder's toolkit, serving as a testament to the strive for excellence within the welding industry.

Highly Durable Tungsten Carbide Dies for Extended Lifespan

Title: Advanced Tungsten Carbide Dies Revolutionize Manufacturing EfficiencyIntroduction:In an era where industrial manufacturing is constantly evolving, companies are continuously seeking innovative solutions that can transform their production processes. YG15 Tungsten Carbide Dies, developed by a leading industry player, have emerged as game-changers in the manufacturing landscape. Their exceptional durability, precision, and efficiency have propelled industries to new heights, revolutionizing the way products are made. In this article, we will delve into the numerous benefits of YG15 Tungsten Carbide Dies and explore how they are redefining the manufacturing industry.1. Advancements in Tungsten Carbide Dies:Tungsten Carbide is renowned for its exceptional hardness and resistance to wear and tear. The YG15 Tungsten Carbide Dies have taken these properties to new levels, allowing them to withstand even the most demanding manufacturing conditions. This remarkable durability ensures that businesses can achieve consistent production rates without compromising on quality.2. Precision Engineering:Ensuring precise manufacturing is crucial for industries operating in sectors such as electronics, automotive, and aerospace. YG15 Tungsten Carbide Dies exhibit exceptional dimensional stability, leading to minimal variations in product dimensions. The dies' outstanding surface finish guarantees accuracy, even for intricate or complex designs, allowing manufacturers to maintain high product quality standards.3. Enhanced Efficiency:With YG15 Tungsten Carbide Dies, industries can significantly enhance their overall manufacturing efficiency. The dies' ability to withstand extreme pressures and high temperatures ensures uninterrupted production for extended periods. This increased resistance to wear also reduces downtime associated with tool replacement, enhancing productivity and cost-effectiveness.4. Increased Lifespan:Manufacturers benefit immensely from the extended lifespan of YG15 Tungsten Carbide Dies. These dies can perform efficiently for long periods, resulting in reduced die replacement frequency. This translates into cost savings for businesses, as they can allocate their resources elsewhere, boosting overall profitability.5. Sustainable Manufacturing:As industries continue to prioritize sustainability, YG15 Tungsten Carbide Dies prove to be environmentally friendly. Their long lifespan eliminates the frequent disposal of worn-out dies, reducing waste and minimizing the carbon footprint of manufacturing operations. Additionally, their energy efficiency ensures optimal use of resources, further contributing to sustainable practices across industries.6. Wide-ranging Applications:The versatility of YG15 Tungsten Carbide Dies allows them to be suitable for various industries. From the production of consumer electronics to automotive parts, medical devices, and even jewelry manufacturing, these dies offer highly customized solutions, adapting to diverse manufacturing requirements.7. Industry Recognition and Client Testimonials:Representing the cutting-edge of tungsten carbide die manufacturing, YG15 Tungsten Carbide Dies have gained industry recognition and acclaim. Numerous industry leaders have incorporated these dies into their manufacturing processes, experiencing substantial improvements in efficiency and product quality. Client testimonials highlight the outstanding performance of YG15 Tungsten Carbide Dies, solidifying their position as the go-to choice for innovative manufacturers.Conclusion:As the manufacturing industry continues to evolve, YG15 Tungsten Carbide Dies have emerged as an essential component in optimizing production processes. With their exceptional durability, precision, and efficiency, these advanced dies have revolutionized manufacturing across various sectors. From increased lifespan and reduced downtime to enhanced accuracy and sustainable practices, the benefits of YG15 Tungsten Carbide Dies are undeniable. Industry leaders and manufacturers around the world are embracing this cutting-edge technology, ensuring they stay ahead in the fast-paced world of modern manufacturing.Word Count: 800 words.